ROBO

SEAM

3D printing of large structures

The extrusion unit is integrated in the 5-axis machines from Metrom. There, the machine is used for hybrid machining, i.e. additive and subtractive processing in one machine.

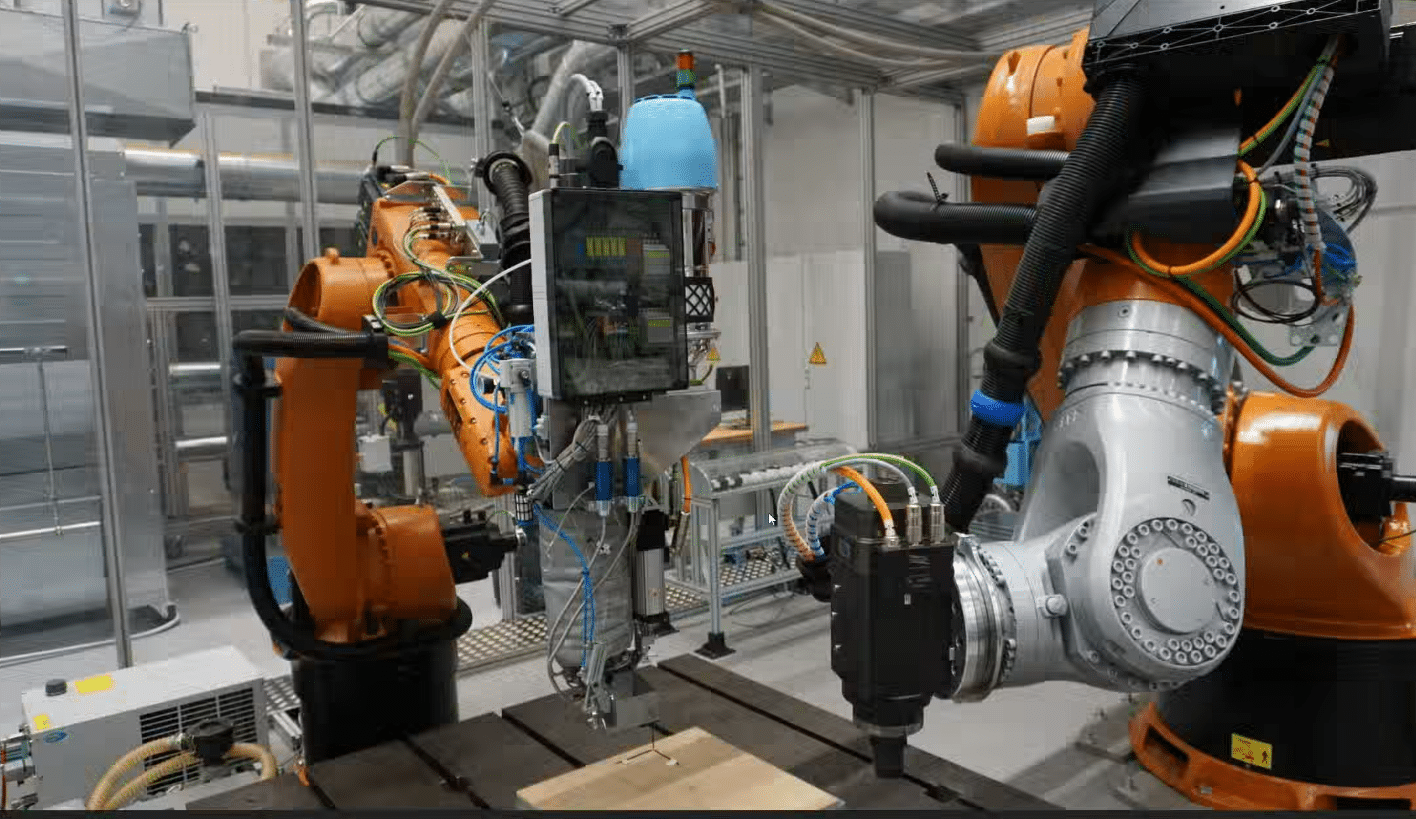

ROBO SEAM – 3D printing of large structures + milling

Collaboration with IBS Automation GmbH Kinematics:

- 6-axis robot kinematics, preferred Comau NJ130, optional KUKA

- Sinumerik One control system with G-code programming

- Customized user interface for 3D printing

- Additional linear and tilt-rotary axes possible

- Automatic switching between 3D printing and milling

ROBO SEAM

3D printing of large structures- large printing area

- can be combined with rotary-tilting table or robot on linear axis

- 5-axis printing on existing surfaces

- feed rates of up to 10m/minute and max. 10kg/ hour controlled output rate

- G-Code controllable robot with Sinumerik control by ibs Automation

- reduced investment costs towards CNC machines

- vacuum clamping syste

- heated print bed

- 45° nozzle