1A Technologies

Industrial high-speed 3D printing with plastic granulate

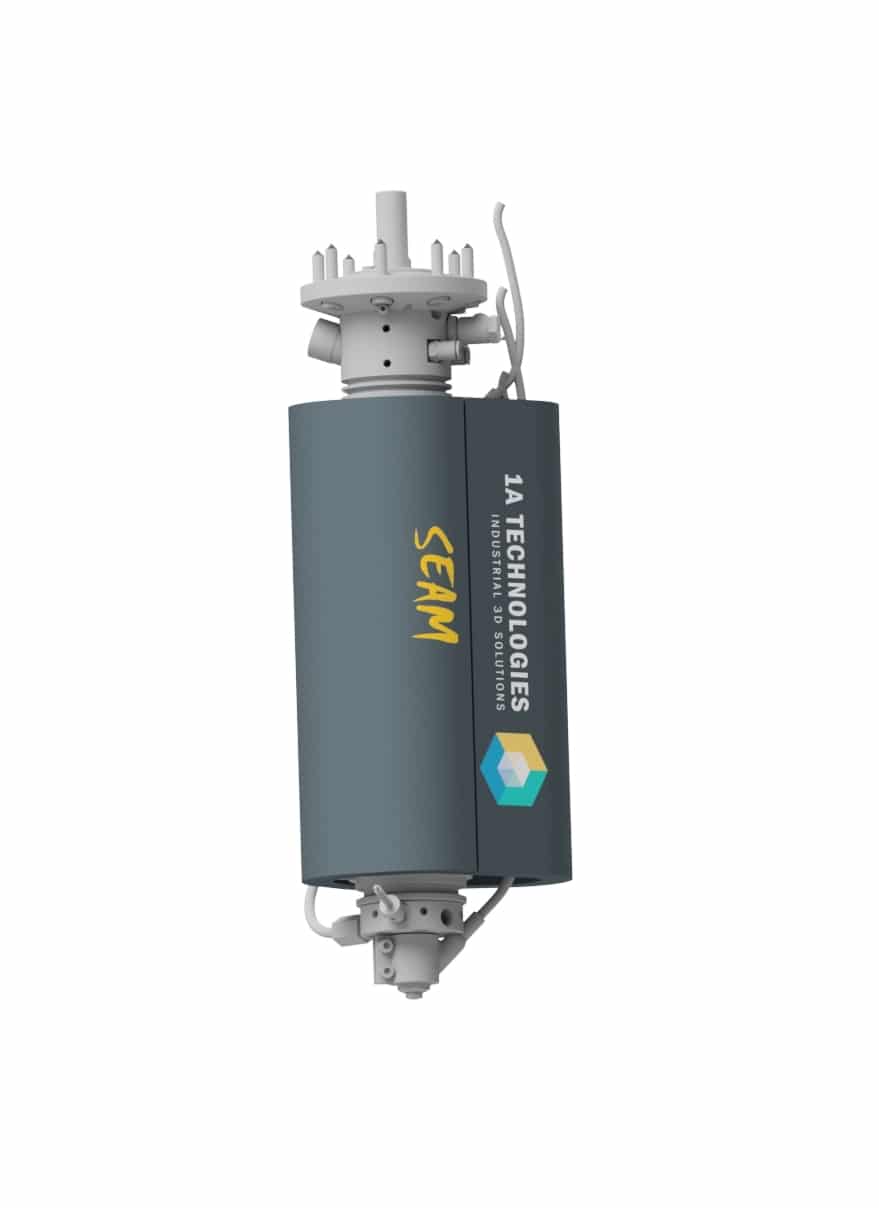

Screw Extrusion Additive Manufacturing = SEAM

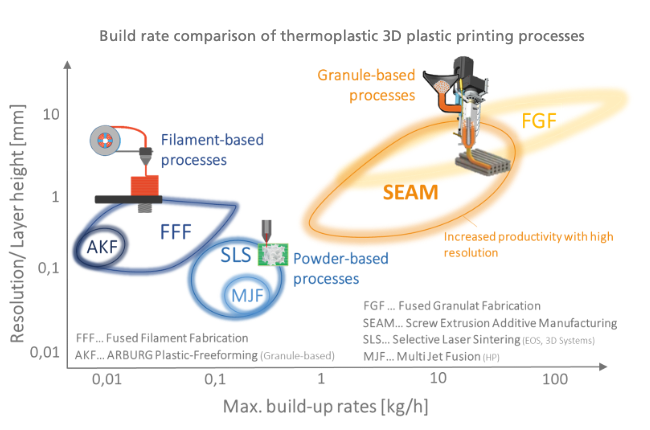

Why SEAM?

Handling and Speed

• High discharge performance up to 18 kg/h suitable for the efficient production of large-format, load-bearing structural components

• Easy handling (compared to powder)

• Continuous material supply (no spool exchange)

• True 5-axis 3D printing can be realized through special material forced feed into the screw for continuous conveyance process even for forced positions

• Almost all plastics can be processed without changing the screw and with highly wear-resistant components

*see diagram Build rate comparison

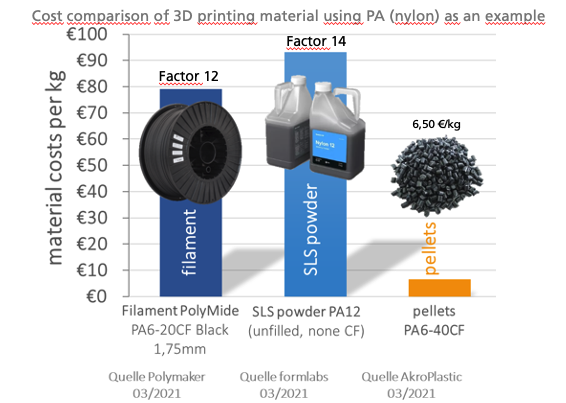

Material Costs and Availability

• More cost-effective than filament

• Wide range of series materials available (PA6GF/CF, PP GF, TPE, TPU) Standard up to 400°C

• Recyclate can be processed

• Regulated melt discharge -> significantly better layer adhesion and shorter dwell times in the screw for the processing of temperature-sensitive materials (e.g., natural fiber compounds) compared to the melt pump.

*see diagramm Cost Comparison

General

-> no additional expensive and heavy melt pump required

• Volume flow control between 0…100% (e.g., 0% for position jumps / 80% in corner areas to avoid contour overfill)

• Automated pressure regulation in the extruder to +- 1bar high consistent strand quality (independent of material batches) even with parameter drifts

• Damage-minimizing processing of fiber-reinforced plastics through gentle material discharge.

Screw Extrusion Additive Manufacturing – Implementation

Penta SEAM - High-Speed 3D Printer + Milling

The extrusion unit is integrated in the 5-axis machines from Metrom. There, the machine is used for hybrid machining, i.e. additive and subtractive processing in one machine.

SEAM Hex - High-Speed 3D Printer + Milling

The extrusion unit is available in combination with a hexapod table as a pure 3D printer. The incredible performance of the parallel kinematic table allows industrial parts to be produced in a very short time without support structures.

EPIC3D

The high output rate of the extruder enables integration in a gantry machine for the production of large components.

HY5CAM - CAD-CAM software system

CAD-CAM software system programming environment for additive + subtractive processes based on RhinoCAD and moduleworks machining plugin.

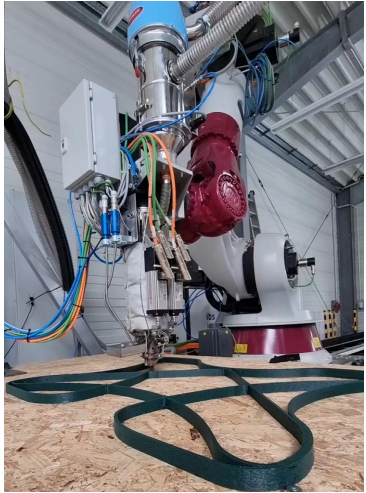

Robo SEAM - Individual in production technology and process combination

The extrusion unit is integrated in the 5-axis machines from Metrom. There, the machine is used for hybrid machining, i.e. additive and subtractive processing in one machine.

![2023-05-04_20-32-09[755]](https://1a-technologies.com/wp-content/uploads/2023/05/2023-05-04_20-32-09755.png)

SEAM variants and upgrade options

SEAM light

- Minimal interface to kinematics

- Includes extruder with 4 heating zones, 1 pressure sensor, and gear motor (On-OFF, speed)

- HMI for controlling all functions.

SEAM 1K

- Minimal interface to kinematics OR adaptive process control with LookAhead

- Includes extruder with 5 heating zones, 2 pressure sensors + gear motor (constant speed)

- Combined pressure and discharge control via patented 1K bypass system.

SEAM 2K

- Adaptive process control with LookAhead Feedforward control

- Includes extruder with 5 heating zones, 2 pressure sensors + gear motor (constant speed)

- Pressure and discharge control via patented 2K bypass system for rapid process control.

What Can We Do For You?

Application scenario: Vacuum clamping device

• Manufacturing of the individual component with a surcharge of 4mm

• Final machining with final dimension tolerance

• Plastic instead of aluminum for lighter, more cost-effective components

• Simple and tool-less machining through material substitution.

Application scenario: Production of laminating devices (with internal honeycomb structure)

• Recreational vehicle bodies

• Special vehicle bodies

• Boat and yacht construction

• Floor plates

• Facade claddings

• and more…

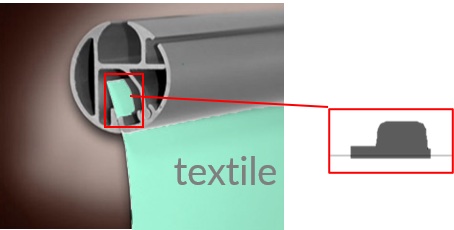

Application scenario: Direct printing of TPU/TPE onto fixtures or textile

- printing on textile structures applications

- piping for covering and fixing of textiles, possibility of easy disassembly and replacement of the textile

- Local reinforcement, directional reinforcement

- Functionalization -> Anti-slip

- edge reinforcement, prevention of textile unraveling

- Cutting aid

- Flexible application of 3D structures

Application scenario: Furniture pieces

• Control panel with integration for 19″ rack PC

• Bar stools

• Conference tables and chairs

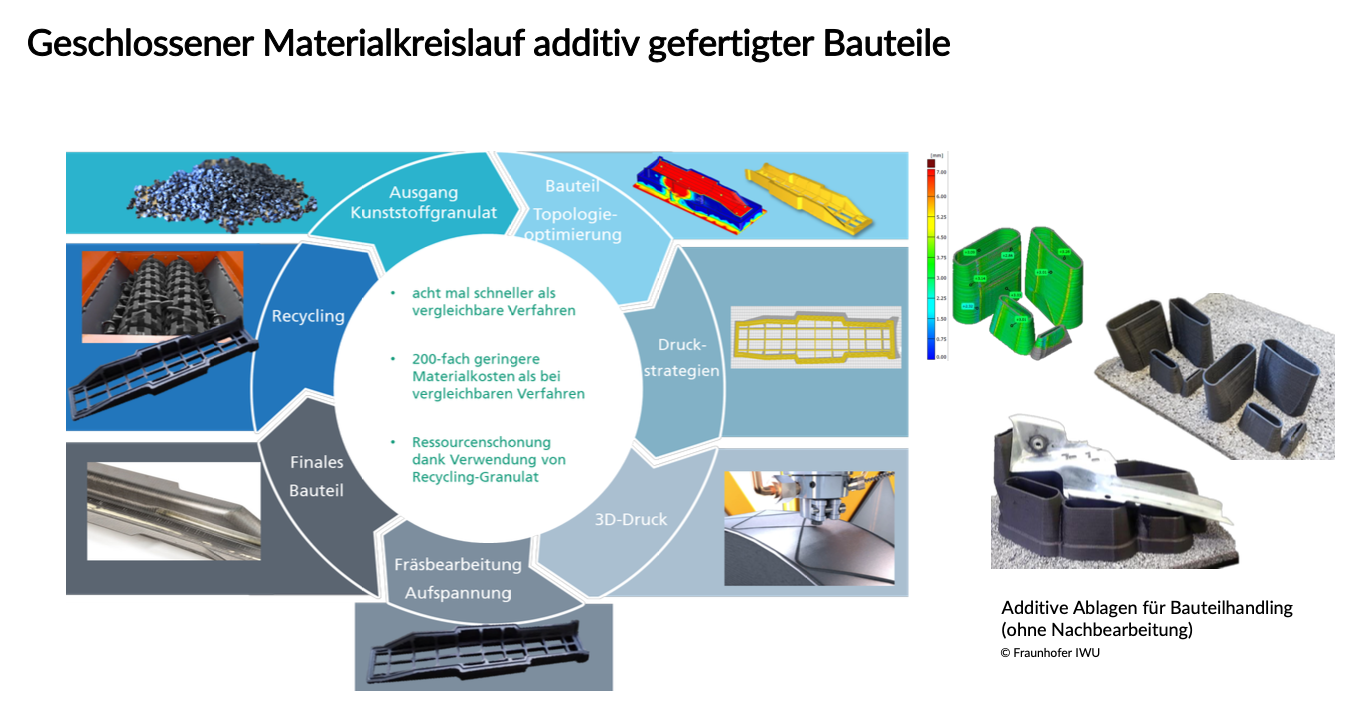

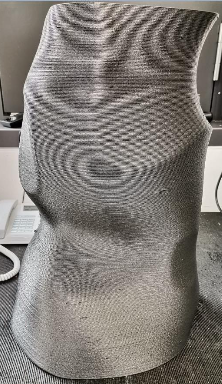

Application scenario: Orthopedic components

Current project Fraunhofer IWU AM-Ortho

• Process chain from scanning to direct printing can be represented

• Saving the plaster blank as an intermediate step

• Saving manual orthosis production by two people with warm film and hot air hairdryer

Application scenario: Structural components machine frame

• Production time 1 week instead of 3.5 weeks steel frame

• Weight saving of 50% compared to the original

• Expansion of the machine’s working area by 80%

• Manufacturing costs 50%